QS-Report:

Fruit, Vegetables, Potatoes | issue September/2017

3

Be it audit or monitoring data – quality

assurance within the QS scheme relies on

detailed information. QS therefore uses

state of the art IT technology in the service

of its scheme participants for the col-

lection, storage and processing of this

data. The security and reliability of this

technology is equally as important as

the trustworthy handling of the data

and information. After all, it all provides

information about the product range and

the efficiency of the companies concerned.

There are more than 30,000 scheme

participants, 96 coordinators, 76 labora-

Data security and usage

Scheme participants can depend on data protection policy

QS Laboratory Performance Assessment

Constantly growing challenges create added value

tasks within the QS scheme. Passing of the

information to third parties is not permitted,

unless the participant concerned has

expressly consented otherwise.

(3)

All QS scheme participants have

permanent access to all basic, audit and

monitoring data that is saved within the

QS scheme relating to their company.

However, this does not include implicit

requirements of data protection which

have always been respected as part of the

QS scheme but are now consistently being

implemented in agreements and contracts

and as part of IT technology.

toriesand22certificationbodieswith216auditorsworkingtogetherin

the QS scheme for Fruit, Vegetables and P otatoes. The daily handling

of data requires clear rules for the collection, processing and use of

data. QS scheme participants can fully trust the data security within

the QS scheme. Taking account of the data protection regulations, QS

has derived three principles for the use of the data in the QS scheme.

(1)

The data of the scheme participants is only used for quality

assurance within the QS scheme. The use of the information for

other purposes is out of the question, unless the participant

concerned has expressly consented otherwise.

(2)

The data will be used by QS. Coordinators, scheme participants,

certification bodies, auditors and laboratories may only use the

information to the extent required for the performance of their

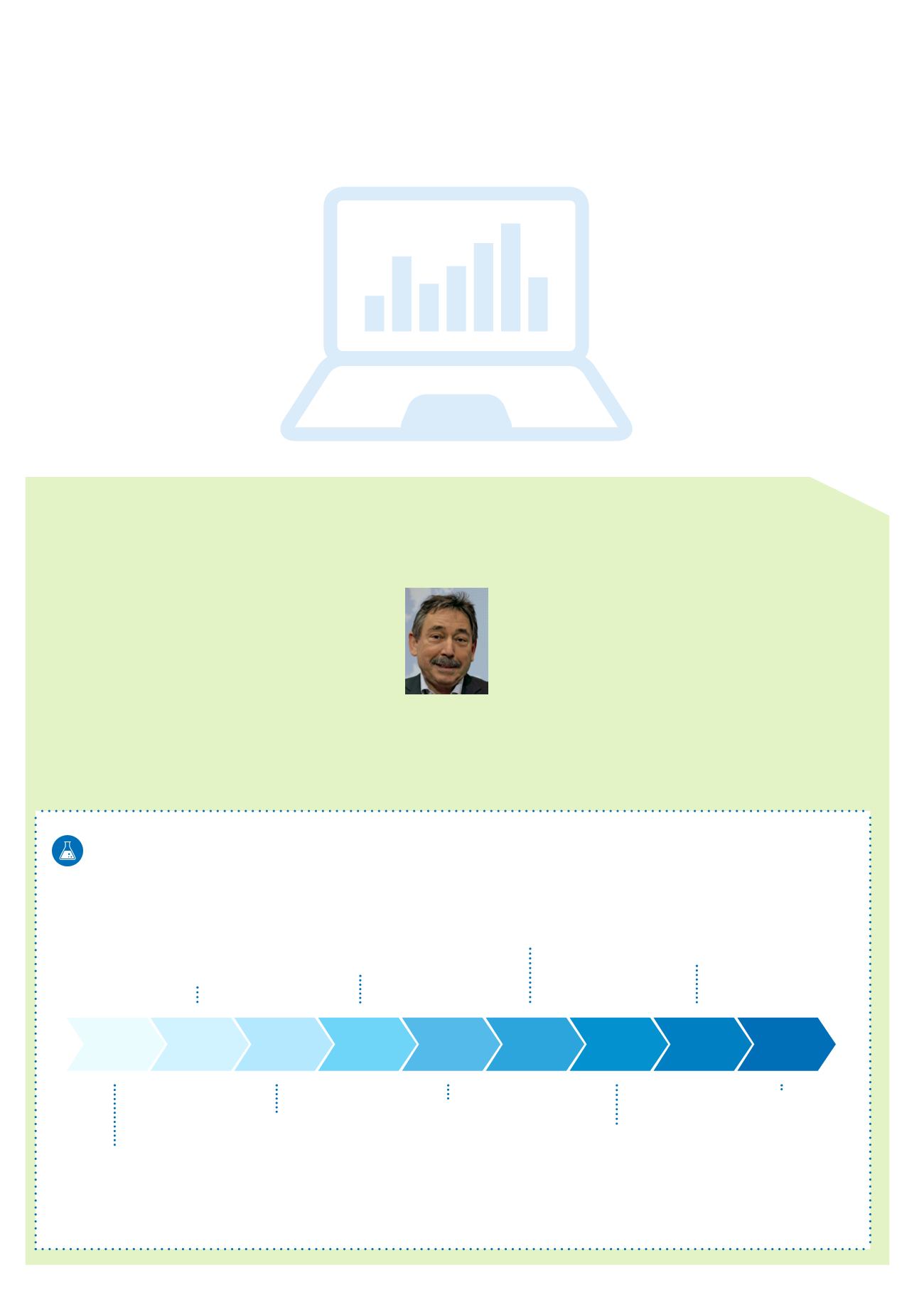

Dr. Gustav Offenbächer

Specialist in residue analysis

“

The test design for the Laboratory Performance Assessment is

being continually developed and adapted to incorporate current

industry issues. The permanent modification of the evaluation

criteria and test design selectively expose deficiencies in the analytical procedures

of the laboratories. This means the laboratories are constantly made aware of critical

analytical issues and thus can continuously improve the quality of their analyses.

”

Introduction of

an annual meeting for

laboratory managers

of the participating

laboratories for the processing of results from

previous laboratory performance assessments.

Introduction of

several test

materials with different active

ingredients. The number of

active substances as well as

their content vary. Processing

time for the sample is reduced

from 10 to 5 days.

Evaluation amended

:

no statistical z-score evaluation

any more, but 70-120% of the

amount of the active ingredient

added must be quantified.

Single method analysis

becomes

an integral part of the laboratory

competence assessment.

Point

system is overhauled

, so that

laboratories scoring below a

minimum number are even more

so obligated to participate in the

subsequent test once again.

Additional focus

on metabolite

analysis

. In addition to the parent

substance, degradation products

or metabolites must also be

considered in the analysis.

Test matrix no longer announced

in advance. Sample processing

time is reduced further.

Introduction of a points system

on

the basis of which the participation

of laboratories in the performance

assessment is evaluated.

Laboratories must send the original reports

to QS in addition to the delivery of their

test results. They are important for the

interpretation of results.

Shipping period for the sample

specified rather than a fixed

delivery time. Successive

adjustment of sample processing

time

from five days to four.

First QS Labora-

tory Performance

Assessment

August

2006

November

2006

2009

Autumn-test

2011

Spring-test

2015

Autumn-test

2007

Autumn-test

2010

Spring-test

2014

Autumn-test

2016

Spring-test

QS Laboratory Performance Assessment

Progression from 2006 to 2016

Twice a year, the analytical quality of accredited laboratories is

bench-tested by using the QS Laboratory Performance Assessment.

In the analysis of residues in fruit and vegetables, the qualification

of laboratory staff is particularly crucial, along with the equipment

and experience of the laboratory. Since the first competency tests

in 2006, the test design has been regularly modified and always

presents the laboratories with new challenges. An approach that

establishes reliability for all market participants but which also pays

off for the laboratories. They receive feedback with important in-

sights for the continuous improvement of their analytical processes.